Vacuum Truck DOT Inspection: What’s on the Checklist?

A vacuum truck is a serious piece of equipment built to do tough jobs in septic, industrial, and environmental work. But keeping that truck compliant and in peak condition takes more than good maintenance habits. It requires understanding and following the vacuum truck DOT inspection checklist, the detailed set of items reviewed by inspectors under the Federal Motor Carrier Safety Regulations (FMCSR). Whether you’re a seasoned operator or new to the business, knowing what’s on that checklist can keep your truck on the road, your business compliant, and your customers happy. Below, we’ll go through everything you need to know about DOT inspections, from must-pass components to pre-trip routines and documentation best practices.

Vacuum Truck DOT Inspection Checklist: Required Items

Every vacuum truck operating on public roads must pass an annual Department of Transportation (DOT) inspection performed by a qualified inspector. During this inspection, all vital systems are checked for safety, proper function, and compliance with federal standards. The main components of the required checklist include:

- Identification and paperwork: Inspectors will verify your USDOT number, registration, proof of insurance, and annual inspection decal. Your vehicle identification number (VIN), license plates, and company markings must be visible and legible.

- Frame and body: The truck’s frame, cross members, and mounting points must be free of cracks, corrosion, or loose bolts. Inspectors will pay close attention to the integrity of the tank and its mounting brackets since these carry heavy loads under variable conditions.

- Fuel and exhaust systems: Check for fuel leaks, secure fuel caps, proper exhaust routing, and no signs of soot or damage near sensitive components. Fuel lines should be intact with no visible wear.

- Steering mechanism: Inspect the steering wheel lash, linkages, gearbox, and power steering fluid. Any excessive play or loose components can cause immediate failure.

- Suspension system: Inspect leaf springs, shocks, air bags, and torque arms for wear or cracks. Uneven height between axles can indicate suspension issues that must be repaired before operation.

- Driveline and axles: The universal joints, driveshaft, and differential housing must be secure and lubricated. Any leaks or excessive movement at the joints are red flags.

- Windshield and mirrors: The windshield must be free of major cracks, and wipers must function correctly. Mirrors should be firmly attached and offer clear, unobstructed views.

A good rule of thumb: if it moves, carries pressure, or affects braking or vision, it’s on the checklist.

Vacuum Truck DOT Inspection Checklist: Brakes, Lights & Tires

Your truck’s brakes, lights, and tires are the first line of defense for safety on the road, and they’re also the most scrutinized items during both annual and roadside DOT inspections.

Brakes

Brakes are one of the most critical systems for compliance. Inspectors will check for:

- Adequate brake lining thickness on all wheels

- No air leaks or audible hissing from the system

- Proper adjustment of air brakes

- Secure hoses and fittings without cracks or chafing

- Correct operation of the parking brake and emergency brake

Operators should test the air brake system daily by performing a full-pressure buildup and leak-down test. If the air loss rate exceeds DOT limits, repairs are required immediately.

Lights

Lighting violations are some of the most common DOT citations, yet they’re also the easiest to avoid. Inspect all lights daily, including:

- Headlights (high and low beam)

- Brake lights

- Turn signals

- Clearance and marker lamps

- License plate light

- Backup light

All bulbs should illuminate fully, lenses should be clean and intact, and wiring should be free from corrosion or damage.

Tires

Tires are checked for tread depth, sidewall condition, and proper inflation. The DOT minimum tread depth is 4/32 inch on steering axles and 2/32 inch on other positions. Inspectors will also check for mismatched tires, bulges, cuts, or exposed cords. Always verify your lug nuts are secure and that wheel seals show no signs of oil leakage.

Vacuum Truck DOT Inspection Checklist: Tank, Hoses & Valves

Vacuum truck tanks and related components receive special attention because they handle hazardous or regulated materials. Inspectors will look closely at:

- Tank condition: The tank shell, heads, and welds must be free of dents or cracks. The tank should display required placards or markings if it transports hazardous waste.

- Hose integrity: Check suction and discharge hoses for wear, abrasions, and proper coupling connections. All hoses should be stored securely to prevent damage during transit.

- Valves and fittings: Ensure that all valves operate smoothly and seal tightly. Leaks around valve seats or fittings are serious violations.

- Pressure/vacuum relief systems: These must be operational and correctly rated for your tank. Test them regularly to ensure they open and close properly under pressure.

- Mounting and securement: The tank should be mounted securely with no movement during operation. Bolts, straps, and brackets should all be tight and corrosion-free.

For vacuum trucks carrying septic or industrial waste, inspectors may also verify the proper containment of residues and compliance with EPA regulations for waste transport.

Vacuum Truck DOT Inspection Checklist: Emergency & PPE Gear

DOT inspections also verify that your truck is equipped with the proper safety and emergency equipment. A missing triangle or fire extinguisher can lead to fines or an out-of-service order. Ensure that you have:

- Fire extinguisher (rated and fully charged)

- Three reflective warning triangles or approved flares

- First aid kit with current supplies

- Personal protective equipment (PPE), including gloves, safety glasses, respirator, and chemical-resistant coveralls when appropriate

- Spill kit containing absorbents, containment booms, and disposal bags

Operators should also verify that safety decals are legible and that emergency shutoff labels are clearly marked and functional.

Pre-Trip Routines, Logs, and Repair Priorities

Pre-trip inspections are the foundation of compliance and safety. Before each shift, drivers must conduct a complete walkaround inspection and log the results in their Driver Vehicle Inspection Report (DVIR).

A good pre-trip routine includes:

- Fluids: Check engine oil, coolant, hydraulic fluid, and brake fluid levels. Top off as needed.

- Leaks: Look under the truck for oil, fuel, or water leaks.

- Belts and hoses: Squeeze and visually inspect for wear or cracks.

- Battery connections: Terminals should be clean and tight.

- Lights and signals: Perform a full lighting test.

- Brakes: Conduct a visual check and an air system test.

- Tank and hoses: Ensure all caps and valves are closed and secure.

When defects are found, they must be corrected before the truck is placed back into service. Some issues can be deferred if non-critical, but anything related to brakes, tires, or steering should be prioritized immediately.

Drivers must also carry documentation of previous inspections and repairs. Keep a folder in the cab with your annual inspection form, maintenance receipts, and DVIRs from the past 90 days. Electronic logging devices (ELDs) can simplify this process and reduce paperwork errors.

Common Violations and How to Avoid Them

Knowing what inspectors most often cite helps operators focus on the right details during daily checks. Common DOT violations for vacuum trucks include:

- Brake system defects: Air leaks, out-of-adjustment brakes, or worn linings.

- Lighting violations: Non-functioning clearance lights or missing reflectors.

- Tire issues: Insufficient tread depth or underinflated tires.

- Leaking hoses or valves: Especially on septic or hazardous waste haulers.

- Missing safety gear: No triangles, fire extinguisher, or PPE.

- Incomplete logs: Missing DVIR entries or expired annual inspections.

To avoid these, train drivers thoroughly on inspection points and reinforce accountability. Using checklists, either printed or digital, ensures that no critical component is overlooked. Make routine maintenance part of your operation’s culture, not just a regulatory requirement.

When you take these steps seriously, you not only prevent costly fines and downtime but also demonstrate professionalism to your clients. Vacuum truck work often happens in public or high-stakes industrial environments, and a clean, well-maintained truck speaks volumes about your business standards.

Partner with KeeVac Industries for Safe, Compliant Equipment

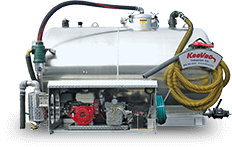

A successful DOT inspection starts long before an inspector arrives; it starts with the quality and reliability of the truck you drive. At KeeVac Industries, we build and upfit vacuum trucks designed for long-term performance, safety, and compliance. Based in Denver, KeeVac uses both new and used chassis supplied by licensed dealers, including Ford, Chevrolet, Ram, International®, Peterbilt, Freightliner, Mack, Isuzu, and Kenworth. Our expert team customizes each build with precision-engineered tanks and components for septic, industrial, and environmental applications.

Looking for a new or replacement unit? KeeVac offers a full range of septic pump trucks, vacuum tanks, and aluminum slide-in pumper units that fit into the full-size bed of most pickup trucks, ideal for contractors who need flexibility without compromising power or performance. Each build is engineered to meet or exceed DOT requirements, giving you confidence that your equipment is inspection-ready from day one.

Whether you’re managing a single truck or an entire fleet, KeeVac Industries is here to keep your business compliant, productive, and profitable. Explore our inventory, request a quote, or talk to one of our specialists about building a vacuum truck that fits your exact needs.