Slide-In Vacuum Unit vs Full-Size Pumper: Which Is Best?

If you’re in the septic, grease, or portable sanitation business, choosing between a slide-in vacuum unit vs a full-size pumper can determine how efficiently your routes run and how fast your business grows. Each type of vacuum truck setup comes with unique advantages depending on your workload, customer base, and long-term revenue goals.

Slide-In Vacuum Unit vs Full-Size Pumper: Key Differences

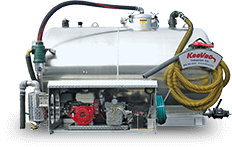

A slide-in vacuum unit is a compact pumping system designed to fit into the bed of a full-size pickup truck. Typically constructed from aluminum or steel, these self-contained units include a tank, vacuum pump, and hose reel, everything needed to handle smaller pumping jobs efficiently. Because they’re modular, slide-ins can be easily removed or swapped between trucks. They’re ideal for startups, light-duty routes, and businesses working in tight spaces or residential neighborhoods.

A full-size pumper truck, by contrast, is a dedicated vehicle built from the ground up for vacuum service. The tank is permanently mounted on a commercial chassis such as an International, Peterbilt, Freightliner, Mack, or Kenworth. These trucks are designed for high-capacity hauling, longer runs, and demanding schedules. They carry significantly larger tanks, often between 2,000 and 5,000 gallons, allowing operators to pump more before needing to unload.

While slide-in units prioritize flexibility and affordability, full-size pumpers focus on volume and professional-grade durability. Your choice depends on the types of jobs you perform most frequently and how you plan to expand your service area over time.

Slide-In Vacuum Unit vs Full-Size Pumper: Setup & Install Time

Slide-in units have a clear advantage when it comes to setup time. Once you have a compatible pickup truck, installation is straightforward: simply slide the unit into the truck bed, secure it, and connect the power source. This means you can be operational within a day. For businesses that want to get started quickly or scale their fleet seasonally, that speed and simplicity make a big difference.

A full-size pumper truck, however, involves a more complex build and installation process. The chassis must be selected, delivered, and upfitted with a custom tank, pump, and accessory configuration. Depending on specifications, that process can take several weeks or longer. The trade-off is a purpose-built rig with optimized balance, weight distribution, and long-term durability.

Slide-In Vacuum Unit vs Full-Size Pumper: Maintenance & Uptime

Maintenance requirements vary between the two systems. Slide-in units are relatively easy to maintain since they use smaller pumps and fewer components. Many operators handle routine oil changes and minor repairs in-house, reducing downtime and operating costs. Plus, since the unit is separate from the truck, you can easily swap it to another vehicle if your pickup needs service, keeping your operation running smoothly.

Full-size pumpers require more involved maintenance, often including specialized service for both the truck chassis and the vacuum system. However, these rigs are engineered for heavy use, with industrial-grade pumps and tanks designed to withstand thousands of hours of operation. For established companies running long routes, the reliability and performance justify the added upkeep.

Slide-In Vacuum Unit vs Full-Size Pumper: Cost & Capacity

One of the biggest distinctions between slide-in vacuum units and full-size pumpers is the initial investment. Slide-in systems are the clear entry-level option. Depending on tank material and pump configuration, a new aluminum slide-in unit may cost a fraction of what a full-size pumper requires. This makes it an excellent choice for startups, side businesses, or operators testing new markets.

Full-size pumper trucks represent a higher upfront cost but offer substantially greater capacity. Where a slide-in might hold between 300 and 600 gallons, a dedicated pumper truck often carries 2,000 gallons or more. That means fewer trips to the disposal site and more revenue per route. For businesses managing municipal contracts, large septic systems, or commercial clients, the larger tank size pays dividends in time savings and efficiency.

Slide-In Vacuum Unit: Affordable Flexibility

The affordability of a slide-in vacuum unit extends beyond the purchase price. Because the unit can fit into most full-size pickup trucks, you can use existing vehicles in your fleet rather than purchasing a new chassis. This lowers your total cost of ownership and simplifies insurance and registration. Additionally, aluminum slide-in tanks are lightweight and corrosion-resistant, helping maintain fuel efficiency and longevity.

Full-Size Pumper: Professional Capacity

A full-size pumper, on the other hand, is a long-term investment in operational capacity. These rigs are designed for volume-driven routes and high-demand clients. The additional tank size and pump power enable faster service for large jobs, supporting higher daily revenue potential. While the initial cost is higher, a full-size pumper can generate more profit over time when kept on the road consistently.

Route Types, Parking Limits, and Expansion Plans

Where and how you operate should heavily influence your choice between a slide-in vacuum unit and a full-size pumper. Urban areas with tight streets, limited parking, and residential clients favor compact setups. Rural regions, industrial clients, and municipal work require the efficiency of large-capacity trucks.

Urban and Residential Routes

If you’re servicing residential septic tanks, portable restrooms, or small grease traps in city environments, maneuverability is key. Slide-in units shine here. Their smaller footprint allows you to navigate narrow driveways, crowded lots, and low-clearance areas with ease. You can park where full-size rigs simply can’t fit. That flexibility saves time and improves customer satisfaction, critical for retaining clients in competitive markets.

Rural and Commercial Routes

For rural routes or commercial contracts, full-size pumpers deliver the capacity you need to complete multiple large jobs in one run. Driving longer distances between jobs makes tank size even more important. Fewer dump trips mean more time servicing clients, which increases profitability. If your business serves industrial customers, multi-tank systems, or municipal sewage contracts, a full-size pumper is the right fit.

Slide-In Vacuum Unit vs Full-Size Pumper: Growth Potential

Your growth strategy also plays a major role in deciding which equipment to buy. Slide-in units are perfect for starting small and scaling gradually. You can add more units as your customer base grows or reassign them to niche services such as portable restroom routes or emergency pump-outs. Because they’re modular, they make excellent backup systems when you expand into larger trucks later.

Full-size pumpers, meanwhile, are ideal for established companies with steady routes and predictable demand. Once your operation has consistent daily volume, a full-size rig becomes more efficient on a cost-per-job basis. The higher upfront investment pays off through faster service times, larger tickets, and increased reliability.

When to Upgrade: Adding Trucks vs Scaling Tanks

Deciding when to upgrade from a slide-in vacuum unit to a full-size pumper depends on both workload and logistics. If you’re turning down jobs because of tank limitations or spending excessive time dumping between stops, it may be time to scale up. However, you don’t have to leap straight from one to the other. Many successful companies run mixed fleets, assigning slide-ins to urban or light-duty routes and full-size trucks to heavy routes.

Adding trucks rather than replacing them outright lets you grow capacity in stages. You might start with one slide-in unit, then add another to cover more territory before investing in a large pumper. This strategy helps balance cash flow and ensures every piece of equipment earns its keep.

Slide-In Vacuum Unit vs Full-Size Pumper: Maneuverability & Operator Experience

Ease of use is often overlooked but makes a real difference in day-to-day efficiency. A slide-in unit, being lighter and smaller, is easier to handle for new operators. The learning curve is gentler, and the setup encourages safe, quick operation in confined areas. They’re also easier to transport and store when not in use.

Full-size pumpers require more driver experience and sometimes a CDL, depending on tank size and gross vehicle weight. However, they provide a smoother experience for large-scale pumping, with advanced hose management systems, better suction performance, and integrated features like automatic valves and flow meters. For operators who spend all day pumping, the comfort and power of a full-size rig make a noticeable difference.

Matching Equipment to Revenue Goals

At the end of the day, your equipment choice should align with your business model and revenue targets. Slide-in vacuum units excel in cost-efficiency, allowing you to serve smaller routes profitably and expand gradually. They’re ideal for operators who prioritize flexibility, lower overhead, and rapid deployment. Full-size pumpers dominate in volume-based models, maximizing revenue per route through high-capacity service and fewer unload cycles. They’re best suited for established companies with steady client bases and long-term contracts.

Balancing Your Fleet for Maximum ROI

Many successful pumping businesses eventually maintain a balanced fleet that includes both unit types. Slide-ins handle residential, event, or spot-service jobs, while full-size pumpers manage heavy-duty routes. This combination ensures maximum versatility and uptime, keeping your trucks productive no matter the route type or season.

Partner with KeeVac Industries

Whether you’re starting your first pumping business or upgrading your existing fleet, KeeVac Industries is your trusted partner in high-performance vacuum equipment. Based in Denver, Colorado, KeeVac builds durable, efficient vacuum trucks and slide-in pumper units tailored to your exact needs. We upfit both new and used chassis from licensed dealers, including Ford, Chevrolet, Ram, International, Peterbilt, Freightliner, Mack, Isuzu, and Kenworth. Our aluminum slide-in pumper units are engineered to fit into the full-size bed of nearly any pickup truck, offering a lightweight, long-lasting solution for operators who value flexibility.

From compact slide-ins to full-size septic pump trucks and vacuum tanks, KeeVac Industries provides the right equipment to match your routes, revenue goals, and long-term growth plan. Explore available builds and discover how we can help you equip your business for lasting success.

If you are in the market for a slide-in pumper unit, it is important to consider several features before making a decision. A slide-in pumper unit is a versatile piece of equipment that can be easily mounted on a truck or trailer, making it ideal for firefighters, municipal departments, and other emergency response teams. Here are some key features to consider when choosing a slide-in pumper unit:

If you are in the market for a slide-in pumper unit, it is important to consider several features before making a decision. A slide-in pumper unit is a versatile piece of equipment that can be easily mounted on a truck or trailer, making it ideal for firefighters, municipal departments, and other emergency response teams. Here are some key features to consider when choosing a slide-in pumper unit: